The Minimally Adjustable Two Jaw Chuck

By our Secretary, Pete Hatherell

I’ve made a few one-piece scoops over recent years, a simple project but with a couple of slightly tricky points.

It is a two-stage process, starting with some spindle turning to create a sphere on the end of a handle, the first

tricky bit as it does need to be a fairly true sphere to ensure that the walls of the bowl are of even thickness all

round. In the second stage, the sphere then needs to be held centred for hollowing out, with the handle at

right-angles to the axis of rotation. I have made sets of jaws, using the Axminster wood jaw plates, to grip the

bowl. The problem I have had, however, has been that the jaws mark the outside of the scoop bowl unless

they are exactly the right size. Making these jaws is not hard but is a time-consuming process and a full set is

needed for each size of scoop, so I gave thought to an alternative means of holding it for hollowing. The

alternatives that I have come across include using a standard chuck with one jaw removed to accommodate

the handle (I got terrible vibration when I tried this, due to the imbalance) and making a doughnut chuck (more

on this later). I was thinking along the lines of a jam-chuck but jamming a sphere with a handle into a hole in a

block of wood has its own difficulties, not least that exact precision is needed to get the size right; one scrape

too far and there’s no putting the wood back. I came up with the following idea to get round these problems.

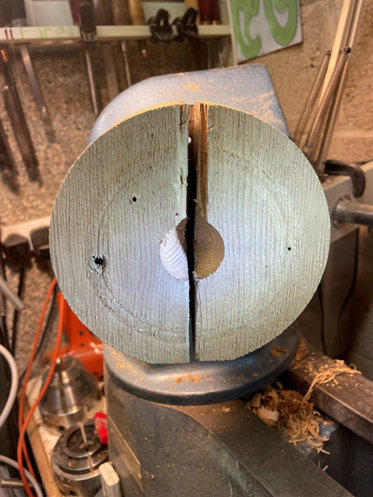

The idea is simple and is based on a jam chuck, but with some adjustability. I used a 12-hole face plate and a

couple of lumps of an old fence post, though any suitably sized scrap wood would do. The face plate is

screwed to the two pieces of wood with a small gap between them, the gap aligned across the centre of the

plate. The reason for the gap will be explained below. Balance and face off the pieces of wood.

Turn a hollow to accept the scoop. This should be just a shade smaller than the scoop bowl and a little over

half the diameter of the bowl deep. Try to make the hole spherical in shape with a bit of undercut. With the

plate off the lathe, cut a channel along the gap to one side of the hole to accommodate the handle. The size

of this is not critical, as long as it’s big enough.

At this stage, the scoop should not quite fit into the hole. With the plate off the lathe, loosen the screws.

This will allow some movement between the two blocks of wood, hence “minimally adjustable” and, if the

hole is the right size, the scoop can now be pushed in. The screws are re-tightened which draws the blocks

back towards their original position, gripping the scoop. Tighten them progressively, swapping sides to get

an even pressure from both blocks, to ensure that the scoop remains centred. If the hole is too small and

the scoop still can’t be pushed in, the blocks can be put back on the lathe and the hole enlarged a tiny bit. If

you’ve gone slightly too far, use a piece of paper towel round the scoop to tighten things up.

The bowl can now be hollowed out in the normal way. This is where the gap between the two blocks

becomes useful. Because it is possible to see down between the two blocks, the bottom of the bowl is

visible and a depth gauge can be set to ensure that the bowl is hollowed out fully, with little risk of overdoing

it and going right through. This is why I don’t like doughnut chucks for this project; you can’t see the bottom

so setting the depth is less easy.

Compared to making a set of four jaws for a scroll chuck, this method is quick, cheap (you don’t need a set of

wood jaw plates), simple and works well. I don’t know if it is an original idea but I’ve not seen anyone using it

on YouTube. I’m not sure how well it would work when making larger scoops and ladles but I’m sure that it is

a method that could be applied to other projects.

Two scoops made from cherry using the above method.

Peter Hatherell - June 2023